With over 12 years of detailing and coating experience in Malaysia using a variety of products from world-class partners, we would like to like to explain how hardness of materials affects its ability to scratch surfaces. Some recent coating systems claim to have a hardness of 9 but our experience with coatings indicates that such claims are unlikely based on some very basic science.

Let’s start at the beginning with a general definition; a scale of hardness is defined by the Moh scale.

“ The scratch hardness is related to the breaking of the chemical bonds in the material,

creation of microfractures on the surface, or displacing atoms (in metals) of the mineral.

The Mohs' hardness scale was developed in 1822 by Frederich Mohs.

This scale is a chart of relative hardness of the various minerals (1 - softest to 10 - hardest).” - as defined by Mineralogical Society of America.

The common softest mineral out there would be talc (baby powder rates as a 1 on the Moh scale) and the hardest substance in nature is a diamond (rated as a 10 on the Moh scale). The next closest object in hardness to a diamond coming in at a 9, would be ruby and tungsten carbide (commonly used in drill bits). Synthetic diamonds or cubic zirconia, comes in at 8.

As far as science goes, there are no quartz coatings come in with a rating of 9. Pretty much most minerals above 5 on the scale are pretty hard materials that do not scratch easily. Coatings are designed to protect a vehicle’s paintwork from common debris (mud/sand/dust) and moisture.

Most car owners are also generally concerned over the possible damage from vandalism including:

a) Coins (3.5 on the Moh scale)

b) Knife blades (5.5 on the Moh scale)

c) Fingernails (2.5 on the Moh scale)

The key to understanding the Moh hardness scale is quite simple: an object that has a lower hardness (low Moh number) will NOT be able to scratch an object that is harder (has a higher Moh number). For example, it would be possible for a diamond (10) to scratch anything, but coins (3.5) will not be able to scratch ruby (9). Also well known: Only a diamond can cut a diamond (10)!

But to understand this further; the Moh scale applies to RAW minerals and metallic elements; NOT coatings. Some coating specialists claim that they have a coating with a hardness of 9. If this were true, a synthetic diamond (cubic zirconia at 8) would not be able to scratch such a coating! Only other elements such as ruby, tungsten carbide and real diamonds would be able to scratch these coatings claiming a hardness of 9.

"A hardness claim of 9 on a glass/quartz/ceramic/crystal coating is physically impossible."

Coatings are formulated to be tough enough to withstand most of the common elements that car owners have to face with daily driving. Si02 coating will cover the bulk of your protective needs. It would be highly unlikely someone would come out to intentionally vandalise a car with a real diamond ring, real ruby bracelet or tungsten carbide drill!

Another common test of hardness for coatings is the infamous pencil hardness test or the Wolff-Wilborn test. This test which is carried out in a laboratory setting where pencils of various hardness are used to intentionally scratch a surface or coating to see how well it resists scratching. Usually with a maximum pressure of about 2 lbs/f using different pencils, the hardness rating (H) is derived based on the pencil used. However, such tests do not represent real world conditions. Even poor car washing practices such as using a damaged rag can potentially scratch a coating on a car.

Coatings vs. Wax

Coatings are not designed to make a car totally invincible to damage but they provide a layer of protection against UV and debris while allowing longer intervals between detailing compared to using wax as a finishing product. Wax typically lasts only 2 to 3 weeks at best in Malaysian weather. Si02 coatings are the most versatile that can be applied to a vehicle with good protective characteristics. Unlike wax, a coating can last up to over a year. It also has amazing clarity and shine while requiring minimal maintenance. A weekly wash is all that is required to maintain the glossy appearance. No polishing or waxing is required monthly.

To answer the question we had at the beginning; a coating is designed to be a finishing that locks in any detailing work so you will not have to wax or polish the exterior. Coatings are designed to be hydrophobic and resistant to debris but it doesn’t make them totally infallible to scratches caused by abuse such as vandalism or intentional scratching.

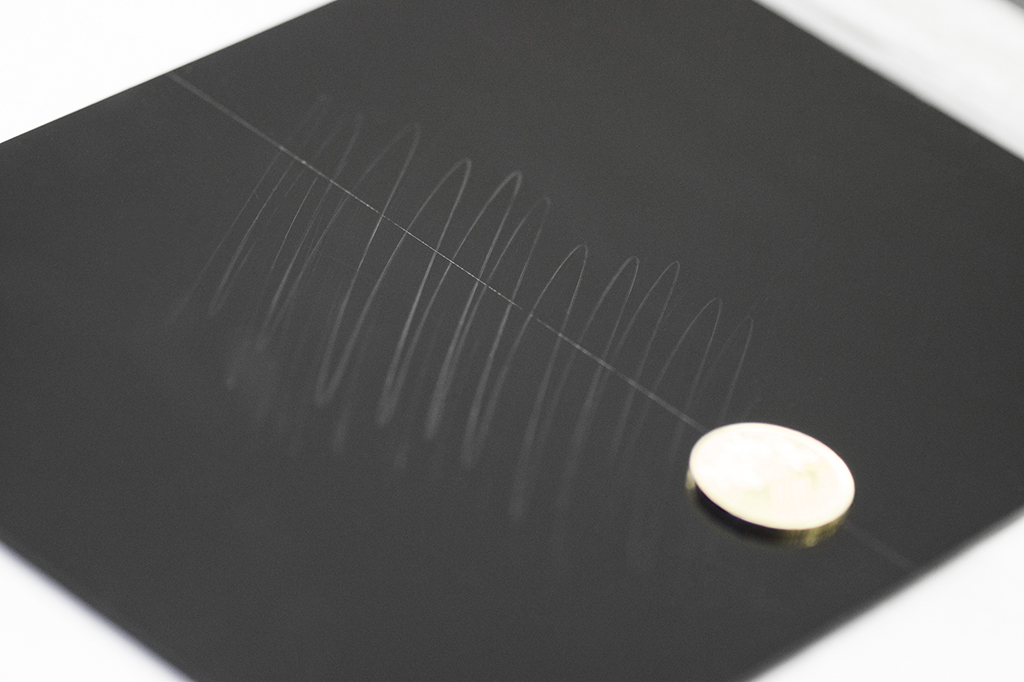

A coin was used to scratch a single coated (LEFT) and multi-coated (7 layers) (RIGHT). Coatings will not hold up to objects with a hardness level of 9 as claimed by some coating specialists. This coin used to scratch both these coatings have an average hardness level of just 3.5 Moh.

Just using fingernails, with a hardness of 2.5 Moh, there are still visible scratches on both the single (LEFT) and multi-coated samples (RIGHT).

AutoDetailer Studio offers our latest Hybrid Ceramic Coating solution that provides cost-effective protection for up to 1-year! All that is needed is a weekly wash to keep your coating looking great!

Another option that would offer even MORE protection to customers that have real concerns over physical damage to their vehicles would be to use a Paint Protection Film that is physically up to 400% thicker than a clear coat. AutoDetailer Studio currently offers ClearGuard Nano SR® and SatinGuard™ Matte paint protection films. These Paint Protection Films may also be combined with coating solutions for an additional measure of protection!